MAI Multiskelett – Multiaxially Loaded Integral Part Manufactured by Plastic Injection Molding with Load Path Optimized, Pultruded Endless Carbon Fiber Bundles in Skeleton Structure

“Skeleton cunstruction” 2.0

Project Partners

BMW AG, ARRK Product Development Group Ltd., P+Z Engineering GmbH, Eckerle GmbH

Duration

01.09.2015 – 30.06.2017

Funding authority

German Federal Ministry of Education and Research

Motivation

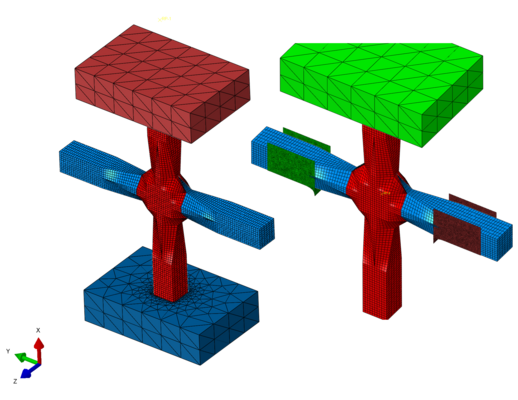

Carbon fiber reinforced plastics (CFRP) show a high potential for lightweight design. Compared to other materials such as metals or non-reinforced plastics and adjusted for its density, CFRP is capable of bearing enormous tensile loads. These density specific advantages can however best be harnessed when the fibers are oriented along load paths. A prerequisite for this is load path optimized part design. Based on the findings of the project MAI Skelett, the project MAI Multiskelett aims for the advancement of the skeleton construction with CFRP. Especially for large structural components, in which several principal load paths cross each other (e.g. front and rear of the side frame of an automotive passenger cabin), process-based solutions for the crossing of beams and profiles as well as for load introduction areas should be developed. The goal was to be able to apply a skeleton structure also for complexely loaded components. For this, a process chain had to be developed that reaches from part construction to manufacturing and that enables a cost-efficient production of CFRP components in the long term.

Method

Through close and trusting cooperation of the partners, a quantum leap for the manufacturing and further spread of CFRP in many applications such as automobile, machinery or aircraft construction could be reached. The experiments on the tensile test machine demonstrated that the node elements are extremely resilient (up to 7.000 N). It was shown that process and manufacturing costs can significantly be reduced using the MAI Multiskelett process. With this process, manufacturing costs of 18 € per kilogram part are realistic. Thus, the ambitious project goals regarding economic efficiency could be met.

Publications

Hogger, T.; Winkler, P; Wehrkamp-Richter, T.: MAI Skelett / Multiskelett a novel design philosophy based on truss elements. ECCM17 - 17th European Conference on Composite Materials, 2016

Acknowledgement

The chair thankfully acknowledges the funding of the project “Multiaxial beanspruchtes Integralbauteil im Kunststoffspritzguss mit lastpfadgerechten, pultrudierten, endlosfaserverstärkten Carbonfaserbündeln in Skelettbauweise – MAI Multiskelett” provided by the German Federal Ministry of Education and Research under the leading-edge cluster MAI Carbon (funding code: 03MAI37D).

Contact Persons

Dr.-Ing. Swen Zaremba

Final Report

External link (pdf)