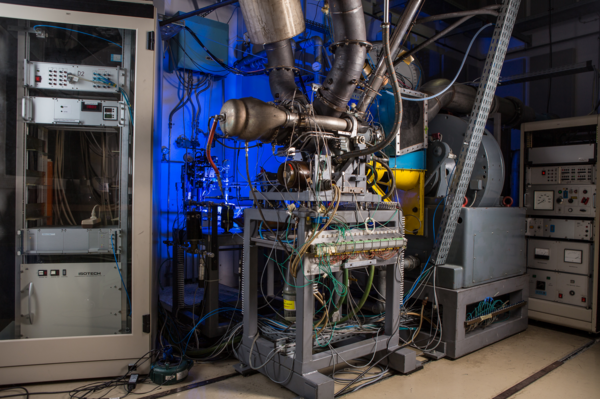

Power Shaft Turbine I - Allison Gas Turbine Test Bench

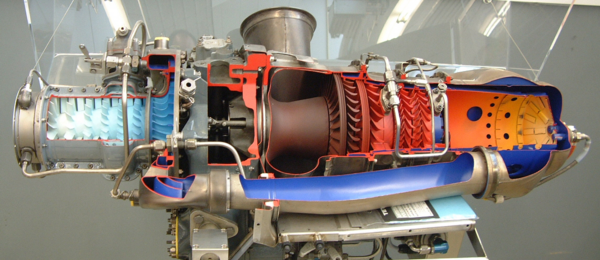

This test stand has existed at LTF since the 1980s and is continuously being expanded and modernised. It is used to investigate the operating behaviour of helicopter gas turbines and to validate computational models. The test object is an Allison 250-C20B turboshaft engine for civil and military helicopters (e.g. Bölkow Bo 105), which is one of the most successful engines in the world, with 30,000 units produced.

A special feature of the test stand is the fully programmable digital control (FADEC: Full Authority Digital Engine Control), which allows a detailed study of the engine processes by varying the parameters. Furthermore, the engine is instrumented with measurement technology beyond the usual scope, which means that, among other things, instabilities of the compressor can also be investigated.

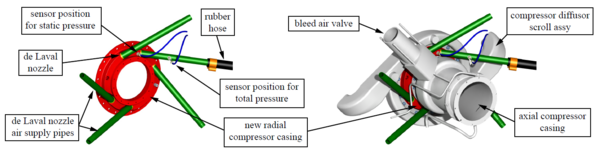

Current research work is concerned with the development of a quick-start system, with the help of which the starting time of the engine can be reduced from 26 to three seconds from standstill to ground idle. For this purpose, compressed air is blown through Laval nozzles onto the blades of the radial stage of the compressor and the high-pressure shaft is accelerated by impulse transmission. The system is designed to enable safe operation of twin-engine helicopters with only one active engine by allowing the second to be started within the shortest possible time in the event of an engine failure.

The unique selling point of the test stand is the coupling with the helicopter simulator of the Institute of Helicopter Technology at TUM. This makes it possible to test the quick-start system close to the real operating conditions in the helicopter by means of hardware-in-the-loop tests, and to investigate its operation and acceptance in pilot studies.

Engine Specification

- Type: Allison 250-C20B

- Producer: früher Allison Engine Company, jetzt Rolls-Royce (M250)

- Power: 313 kW beim Start für 5 min, max. Dauerleistung 298 kW

- Compressor: 6 axial stages, 1 radial stage

- Druckverhältnis: 7,2:1 Max.

- Massflow: 1,56 kg/s

- Turbines: two staged high pressure turbine, two staged free-wheeling turbine, uncooled

- Rotational Speeds: N1 max = 53000 1/min, N2 max = 33290 1/min, output shaft 6016 1/min

- Weight: 72 kg

- Dimension: 1034 x 589 x 483 mm

Fast Starting System

- Mass flow: 0.5 kg/s

- Number of nozzles: 1-5

- Outlet Mach number: 2.3

- Pressure vessel: max. 300 bar, 15 l

- Start time 0 - N1P = 60%: < 3s

- Weight: approx. 45 kg

Measuring Technology

- Acquisition of stationary data with 10 Hz

- Acquisition of dynamic data with up to 1 kHz

- Ifta high-frequency system for analysing measurement data with up to 51.2 kHz

- Approx. 30 temperature sensors, 24 pressure signals for operating pressures, up to 16 highly dynamic pressure sensors in the compressor stages

- Recording of speeds, torque as well as two measuring methods for the fuel mass flow (fuel balance and impeller sensor)

- Control by dSpace real-time system, controller model is a real-time capable state space model