CoolTool – Development of a bionically cooled tool in shell construction using an industrial-suited thermo-mechanical design tool

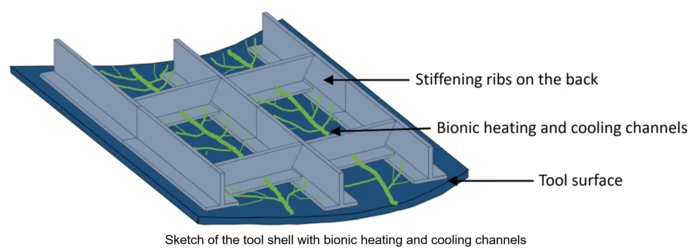

This project involves the development of an RTM tool in shell construction with bionic cooling channels, considering temperature-dependent closing forces during the compaction of the fiber preform.

Project Partners

Grunewald GmbH & Co. KG

Duration

01.02.2025 – 31.05.2027

Funding authority

German Federal Ministry for Economic Affairs and Energy

Motivation

The project aims to further promote the use of resin transfer molding (RTM) in the aviation industry and to shorten production times. To this end, a newly developed shell construction with bionic heating and cooling significantly shortens the heating and cooling process in particular. The newly designed lightweight shell construction with bionic channels allows the tool to be heated and cooled quickly and evenly, which can significantly increase the production rate in the RTM process. Another advantage of the shell-type tool is that it can be operated as a standalone tool without the need for an expensive press investment. To ensure that the mold shells do not deform due to the forces exerted and thus fail to meet the high requirements for component tolerances in aviation, a reliable design is essential. For this purpose, an efficient, industrially applicable design tool for the molds is being developed. This tool supports the design of the mold, taking into account the high compaction forces of the fiber material.

Method

The methodological implementation is based on an interdisciplinary approach combining simulation, experimental validation, and optimization. Thermal and mechanical simulation models are combined to resolve conflicting objectives between stiffness, cooling, and weight. First, bionically inspired heating and cooling channels are integrated into shell molds to ensure homogeneous temperature distribution during the RTM process. In addition, a temperature-dependent material model is developed based on experimental characterization tests conducted at various temperature levels, providing the material data necessary for the simulation model, which utilizes AI-supported parameter adjustment. Finally, an industrially applicable compaction simulation is created that takes thermal influences into account, thereby enabling the design of reliable tools. This methodical combination of simulation, experimentation, and data modeling creates a practical basis for optimized RTM tools in shell construction.

Acknowledgement

The chair thankfully acknowledges the funding of the research project “CoolTool” (funding code: KK5135834KU4) granted by the German Federal Ministry for Economic Affairs and Energy via the funding scheme “Zentrales Innovationsprogramm Mittelstand (ZIM)”.

Contact Persons

Dominik Boos, M.Sc.; Dipl.-Ing. Thomas Wettemann