Process control and setup of additive manufacturing systems for plastic components

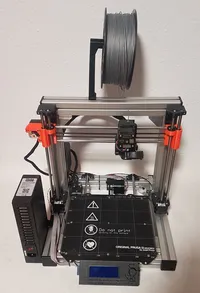

An overview of the industrial application fields of additive manufacturing is given. The focus is on conveying the process-based advantages and disadvantages in different application scenarios. The focus in the following is on extrusion-based processes. The interlinking of the individual processes and their automation will be clarified, as will the process-related component properties. The knowledge acquired is applied practically by working through the printing process with CAD design, STL conversion, post-processing and slicing (printing code generation) and producing components for a printer. In the process, students will learn about different materials used in 3D printing. Subsequently, a printer is assembled by the students independently and under guidance. After completion, the printer is independently put into operation, calibrated, and the full functionality is demonstrated by means of practical tests and manufacturing trials.

| Cycle | WS |

| Type | Practical Course |

| ECTS-Credits | 4 |

| SWS | 4 |

| Max. number of participants | 12 |

| Exam | Compulsory participation, written test |

| Details | further information (lecture content, room number, registration) can be found in TUMonline. |

| Documents | Moodle.TUM (requires registration). |