CUP – Adhesion of composite materials and fire protection films for utility poles; Development of a sustainable adhesive for non-polar resins and foils as well as the material characterization of this composite.

In this project an adhesive shall be developed and characterized. After that, this adhesive is applied to different plastic films with an application in wooden utility poles.

Project Partners

CPS GmbH, Collano AG

Duration

01.07.2025 – 30.06.2027

Funding authority

Federal Ministry for Economic Affairs and Energy

Motivation

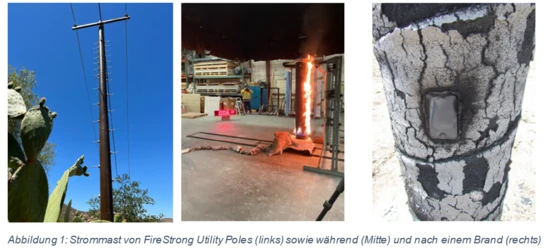

Adhesives improve the adhesion bonds between two surfaces. These consist mostly of petrol-based chemicals like epoxy-resins or acrylates which are expensive and non-environmentally friendly. In this case, this results in the substitution of these chemicals like formic aldehyde and aromatic substances. Regardless there are bio-based alternatives from agricultural waste like birch bark or lignin or epoxidized plant oils. Small structural changes result in a high potential for adhesive application. These applied on PPS-foils shall improve the fire resistance in utility poles remarkably.

Method

This project focusses on the adhesion in PPS-foils. Therefore, the chair of Carbon Composites will use a water-resistant material like lignin or old plant oils for developing the adhesive. An aldol reaction combines the bio-based aldehyde like furfural or ascorbic acid combines both substances with an adhesive as result. This combination is characterized due to ist thermal and mechanical properties. This formula is optimized in a large scale at the Collano AG and tested in high quantity in plastic foils production line at the CPS GmbH and tested for further use.

Acknowledgement

The chair thankfully acknowledges the funding provided by the Federal Ministry of Economic Affairs and Energy as well as the AiF Projekt GmbH for the ZIM R&D Project “CUP” – (funding code: KK5135836).

Contact Persons

Isabell Petri, M.Sc.; Dipl.-Ing. Thomas Wettemann