MIKWERK – Microwave-heated tool for time- and cost-efficient curing of CFRP and GFRP components in medium-sized series production

In the MIKWERK project, an additively manufactured, self-heating LFAM tool with integrated microwave absorption is being developed to cure fiber-reinforced composite components efficiently, quickly, and with moderate investment costs for medium production volumes.

Project Partners

HL Kunststofftechnik GmbH, PCW GmbH

Duration

01.07.2024 – 31.01.2027

Funding authority

Federal Ministry for Economic Affairs and Energy

Motivation

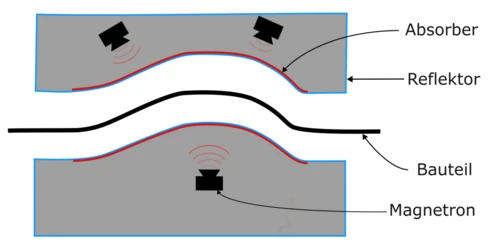

Large-scale industrial solutions with enormous investment costs or individual production with high energy consumption and long throughput times can be used to cure fiber-reinforced plastics. For quantities of 100 pieces, the disadvantages of both approaches outweigh the advantages, resulting in high unit costs. A manufacturing process with medium investment costs but low energy consumption and short throughput times would therefore be particularly valuable for the industry. Tools from Large Format Additive Manufacturing (LFAM) meet the requirements in terms of investment costs and service life. However, the plastics used in these tools result in long throughput times and high energy costs due to their high heat capacity and low thermal conductivity. Therefore, the MIKWERK research project aims to combine the advantages of LFAM tools with those of self-heating tools and print them in a single additive manufacturing step. Microwave absorption has been chosen as the heating mechanism for this project. For this purpose, the tool is manufactured in a shell design using a microwave-reflective material. An absorber layer is printed in the immediate vicinity of the component. Magnetrons emit the required microwaves and are installed after the additive manufacturing process.

Method

The core of the project is the development of a material for microwave absorption and another material for microwave reflection. To this end, several polymer matrices with relevant filler materials are strategically combined and evaluated. The complex permittivity at 2.45 GHz is considered the key evaluation criterion for these materials. Subsequently, design guidelines will be derived in line with design for additive manufacturing. These include the required thicknesses of the absorber and reflector layers, the positioning of the magnetrons, and measures to optimize heat capacity as well as cooling and heating times. The results will then be demonstrated using an application example from HL Kunststofftechnik GmbH.

Acknowledgement

The chair would like to thank the Federal Ministry for Economic Affairs and Energy for funding the project (MIKWERK), under the "ZIM:Produktionsforschung" program. (Förderkennzeichen: KK5135826HD3)

Contact Persons

Maximilian Schäffler, M.Sc.; Dipl.-Ing. Thomas Wettemann