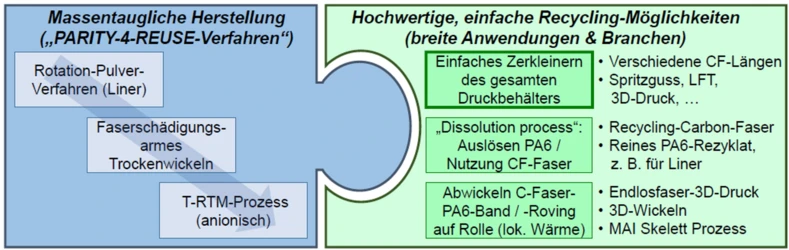

PARITY-4-REUSE – PA6-based High-Performance Type-4 Pressure Vessels aimed at resource-friendly, low-loss recycling through large scale capable T-RTM In-Situ-Polymerization

Processes for Large Scale Production of recyclable Type-4 Pressure Vessels.

Project Partners

Elkamet Kunststofftechnik GmbH, Roth Composite Machinery GmbH, Christian Karl Siebenwurst GmbH & Co. KG

Duration

01.10.2023 – 30.09.2026

Funding authority

German Federal Ministry for Digital and Transport

Motivation

Pressure vessels are a key element for hydrogen and fuel cell technology in order to provide sufficient amounts of hydrogen to achieve a long range. The high operating pressure of 700 bar and the lightweight requirements for automotive applications require the use of carbon fibers in a plastic matrix.

Method

For the industrialization of large quantities and reduction of product costs, this project aims to make Type-4 pressure tanks (concept: plastic liner wrapped with reinforcing fibers) recyclable and suitable for mass production. By combining dry winding and T-RTM impregnation, a more ecological alternative to pressure tanks produced in wet-winding processes is investigated. Within the framework of the project, a pure polyamide 6 / carbon fiber (PA6-CF) Type 4 pressure tank will be developed and manufactured. This initially includes the design of the tank itself, taking requirements and loads into account, supported by real requirements for use in passenger cars in coordination with the BMW Group. In parallel, the necessary manufacturing process chain will be developed, from liner production to winding to caprolactam injection and curing of the components, including the investigation of innovative connection possibilities enabled by the thermoplastic properties of the matrix. Finally, the manufactured pressure tanks will be examined for performance and holistic, simple recyclability (sustainability), and the manufacturing processes will be evaluated in terms of their sustainability and cost-effectiveness.

Acknowledgement

The chair thankfully acknowledges the funding of the project “PARITY-4-REUSE – PA6-basierter, sortenreiner High-Performance-Typ-4 Drucktank für ressourcenschonendes, hochwertiges Recycling dank großserientauglicher T-RTM in-situ-Polymerisation” within the framework of the National Innovation Programme Hydrogen and Fuel Cell Technology (NIP II) with a total of 1 097 350.46 € by the German Federal Ministry for Digital and Transport (BMDV). The funding directive is coordinated by NOW GmbH and executed by Projektträger Jülich (PtJ) (funding code: 03B11040).

Contact Persons

Cagla Sipahi, M.Sc.; Dipl.-Ing. Thomas Wettemann