UV-TOW – Development of a UV-curing and thixotropic resin system with an impregnation process for fiberglass rovings in an Automated Fiber Placement (AFP) process for fiber reinforcement (2D) and component manufacturing (3D) with rapid in-line UV curing

Development of a UV-curing and thixotropic resin system with an impregnation process for fiberglass strands in an Automated Fiber Placement (AFP) method for fiber reinforcement (2D) and component manufacturing (3D) with second-fast in-line UV curing.

Project Partners

S u. K Hock GmbH, LUPEG GmbH, BaltiCo GmbH

Duration

01.02.2025 – 31.07.2027

Funding authority

Central Innovation Program for SMEs (Small and Medium-sized Enterprises)

Motivation

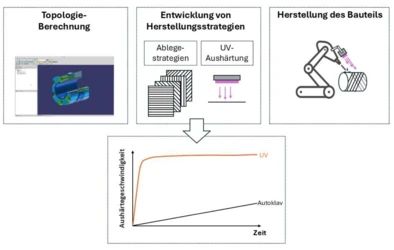

Conventional resin systems in the AFP process require long curing times and cost-intensive consolidation steps, which limits their application to only a few high-tech fields. The goal of this project is the development of a UV-curing, thixotropic resin system that enables second-fast in-line curing. In combination with a specially adapted impregnation process for fiberglass strands, this aims to achieve the cost-effective and efficient manufacturing of fiber-reinforced components in 2D and 3D. The innovative combination of material and process development lays the foundation for broad industrial applications – also outside the aerospace sector – and makes an important contribution to reducing production time, energy consumption, and material usage.

Method

The goal is to develop an integrated process for the automated production of glass fiber-reinforced components with rapid in-line UV curing within the AFP process. TUM is developing a tailored towpreg manufacturing process with adjustable tackiness, complete fiber impregnation, and significantly increased throughput. In addition, a process for rapid UV curing during 2D AFP is being designed to achieve high mechanical performance. Hock provides a UV-curable, thixotropic resin system with enhanced curing behavior. Lupeg contributes a dosing system with integrated viscosity measurement and ultrasonic treatment. Baltico develops a multifunctional AFP head with UV curing and advanced path planning strategies.

Acknowledgement

The chair thankfully acknowledges the funding provided by the die vom Bundesministerium für Wirtschaft und Klimaschutz for the ZIM R&D Project “UV-TOW” – (funding code: KK5135835EB4)

Contact Persons

Christoph Kohler M.Sc.; Dipl.-Ing. Thomas Wettemann