InÜberseEnDruck – In-situ monitoring and AI-based defect detection in the continuous fiber 3D printing process with development of a variable print bed for material-free support generation

Development of a variable printing bed and camera-based in-situ monitoring of the continuous fiber 3D printing process for defect detection and fiber localization.

Project Partners

BRIGHT Testing GmbH

Duration

01.06.2024 – 31.12.2026

Funding authority

BMWi ZIM

Motivation

Continuous fiber 3D printing has great potential for structural components, but is currently too error-prone and difficult to validate. Common problems such as under/over-extrusion, incorrect fiber positioning and insufficient fusion of the materials significantly impair component quality, with many defects not being directly visible after the printing process. As a solution, an automated process monitoring system is being developed that detects in-situ defects and the fiber position. In addition, a variable print bed is to replace the previously used printed support structures. This saves material and reduces production time and costs, as the time-consuming removal of support structures is no longer necessary. The envisaged solution aims to increase efficiency, sustainability and automation for industrial applications.

Method

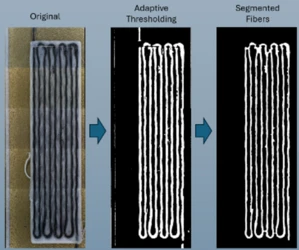

The aim of the project is to develop a variable printing bed consisting of at least 10 separately movable heating bed segments, which can also be angled. This print bed concept is also to be supplemented by two lateral supports with at least three degrees of freedom to generate support for overhangs over already printed areas. The challenge will be the development of the telescopic rods including the angling mechanism, as well as the software solution for the control and implementation in slicing programs. Camera-based process monitoring is required to locate the fibres and detect defects. To do this, images will be captured in the correct position and analyzed as required using AI algorithms. Together, the two developments should make continuous fiber 3D printing more robust, regardless of the machine and material used.

Acknowledgement

The Chair would like to thank the Federal Ministry for Economic Affairs and Energy for funding the project under the “ZIM” program. (Funding reference: KK5135827KL4)

Contact Persons

Jan Seiffert, M.Sc.; Dipl.-Ing. Thomas Wettemann