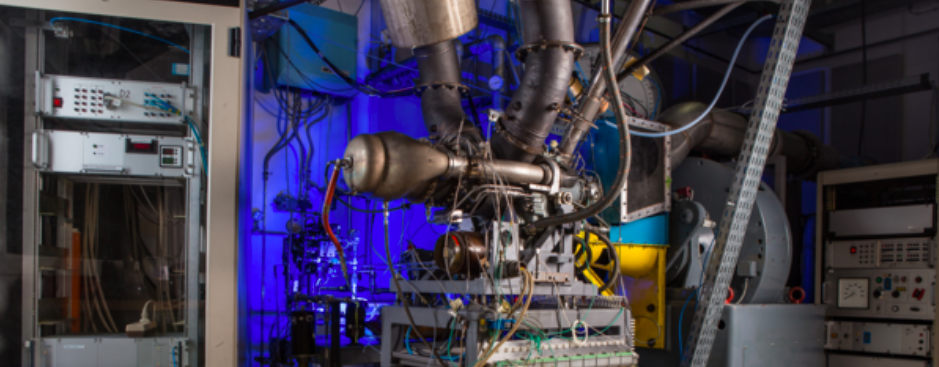

Power Shaft Turbine I

This test stand has existed at LTF since the 1980s and is continuously being expanded and modernised. It is used to investigate the operating behaviour of helicopter gas turbines and to validate computational models. The test object is an Allison 250-C20B turboshaft engine for civil and military helicopters (e.g. Bölkow Bo 105), which is one of the most successful engines in the world, with 30,000 units produced.

You can find detailed information here.

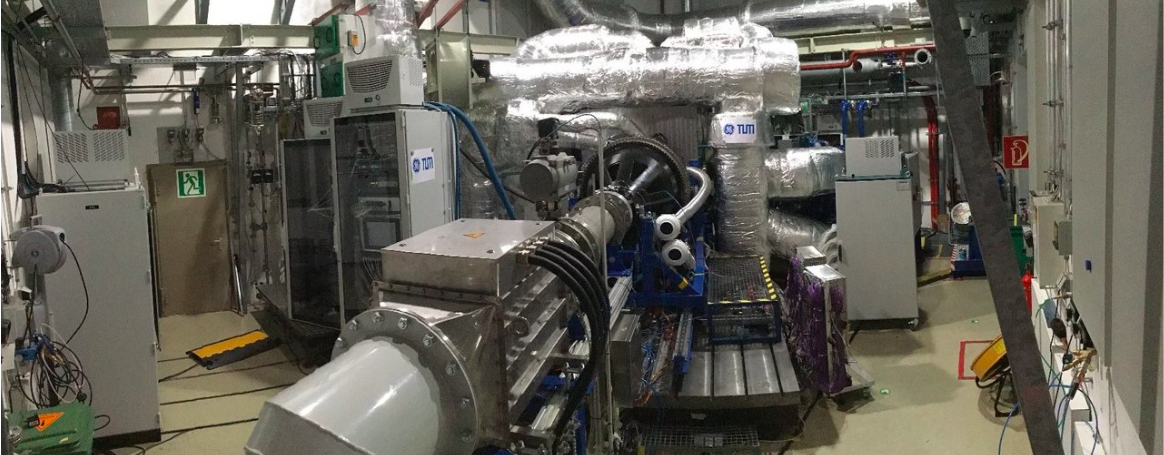

Compressor Test Bench VP 3000

The VP3000 test stand (compressor test stand, 3000 kW drive power) is designed for the investigation of various compressor stages and concepts. The design is modular to allow easy change of compressor stages and thus to cover a wide field of research. The project is run in cooperation with General Electric.

You can find detailed information here.

Highspeed Research Compressor

The project was kicked off in 2013 with the definition of the design requirements for the test vehicle, which is a three-and-a-half stage axial compressor. In 2014 all auxiliary systems were defined in order to prepare the facility for the compressor. Including the expansion of the 20kV power supply, the drive train, inlet- and exit silencers, DAQ and control system, secondary air system and lube oil system.

You can find detailed information here.

HPC Housing Cluster

Extension of the existing HPC cluster by 14 HPC compute nodes MEGWARE SlideSX®-LC CS2600-LC with a value of 122,117.80 €.

You can find detailed information here.

Low-Speed Axial Compressor Test Rig FRANCC

The FRANCC (Fundamental Research and New Concepts Compressor) low-speed axial compressor test rig is a test rig set up at the Chair of Turbomachinery and Flight Propulsion since 2020, specifically designed for the investigation of new compressor blading concepts.

You can find detailed information here.