GreenCarbon – Conversion of CO2 in polymers and carbon fiber based lightweight materials for the aerospace, automotive and construction industry - New ways to integrate lightweight materials to realize a climate-centered energy transition

The GreenCarbon project pursues the approach of generating carbon fiber and new polymeric matrix materials for the production of carbon fiber reinforced polymer (CFRP) from CO2 in order to make CO2-negative CFRP.

Project Partners

Werner Siemens-Chair of Synthetic Biotechnology (TUM); Chair of Biochemical Engineering (TUM); WACKER-Chair of Macromolecular Chemistry (TUM); Chair of Technical Chemistry I (TUM); Fuchs Schmierstoffe GmbH, AHP GmbH & Co. KG; TechnoCarbon Technologies GbR; Airbus Central Research & Technology; Daimler AG Mercedes-Benz Cars, Development RD/FNK-NVH Komponenten; SGL Carbon GmbH.

Duration

01.07.2019 - 30.06.2022

Funding Authority

Federal Ministry of Education and Research

Motivation

Carbon fiber reinforced polymer (CFRP), consisting of a matrix material (thermoset e.g. epoxy resin or thermoplastic e.g. PPS) and the reinforcing fiber (preferably carbon fiber) is a particularly suitable lightweight material for aircraft and automobile construction. For these technical applications, high quality carbon fibers and the polymeric binder (thermoset or thermoplastic) can only be obtained from petrochemical process. In addition, carbon fiber production is energy and cost intensive, which has an impact on the carbon footprint of the overall process. The aim of GreenCarbon is to produce CO2-based carbon fibers and CFRP from algae and to evaluate their performance and possible uses in the aerospace, automotive and construction industries in order to shift lightweight materials towards a climate-neutral, renewable raw material with a significant impact on its field of application.

Method

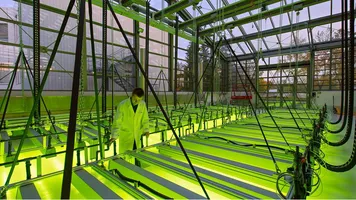

Thanks to its rapid growth, microalgae, such as those cultivated in the unique algae technology center on the Ludwig Bölkow campus of the TU Munich, can actively store the CO2 gas in the form of biomass. The CO2 is, among other things, bound in the form of sugars and algae oil. From these, raw materials for the carbon fiber and plastic production can be obtained through chemical and biotechnological processes. The characterization of the materials at different levels is crucial in order to evaluate the applicability of CO2-negative plastics, carbon fibers and CFRP in the aerospace, automotive and construction industries. The LCC has the challenging task of determining reliable characteristic values during the characterization with the little amount of material available as well as producing CFRP parts. The influence of the sample size on the characteristic values will be investigated as well. Furthermore, as part of the project, a life cycle analysis (LCA) will also be carried out.

Acknowledgement

The chair thankfully acknowledges the funding provided by the German Federal Ministry of Education and Research (funding code: 03SF0577A).

Contact Persons

Nikita Reinhardt, M.Sc.; Dr.-Ing. Swen Zaremba