Disacop – Disassembly of eco-designed helicopter demonstrators

Thermoplastic composite materials (TPCs) are potentially highly recyclable when compared to more popular methods that use thermosets. What is more, they promise unlimited storage life, robustness and chemical resistibility, resulting in lower manufacturing costs, reduced weight and positive environmental impact. The Disacop project aimed to explore the potential of recycling helicopter parts through the fusion bonding of TPCs.

Project Partners

Polymer Competence Center Leoben GmbH, Qpoint Composite GmbH

Duration

01.11.2012 – 31.10.2014

Funding authority

FP7-JTI - Specific Programme "Cooperation": Joint Technology Initiatives of the European Union

Motivation

Existing methods do not allow for recycling, repairing and reusing manufactured parts. By contrast, Disacop's innovative recycling strategy assembles components and disassembles integral parts of structures via fusion bonding techniques. Single elements can be detached from the main structure and reused on a repaired component. Bolts and rivets that assemble current aerospace structures are no longer needed, saving on both costs and weight. Excess waste is avoided by separating damaged components from intact components of a TPC structure. In addition, the local heating procedure uses up minimal energy and the joining and separation of TPCs do not give off any toxic substances.

Method

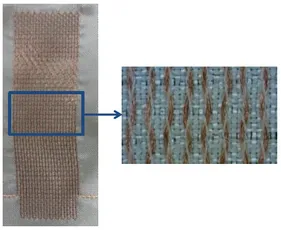

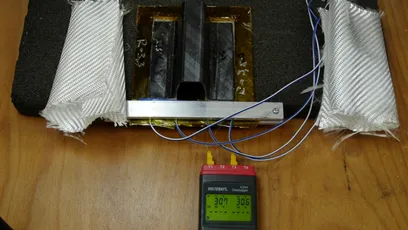

Work began with the mapping of various heating methods for the fusion bonding of TPCs. Initial tests were carried out to demonstrate the debonding procedure, leading to the most suitable method for the disassembly of TPC structures. This heating mechanism of this method was then fully studied. Tests on available coupons and subcomponents were performed to understand the effects of the procedure on real joints. The technology was further developed based on requirements beginning at coupon level. Project partners then applied the developed component separation scenario on demonstrators. They were able to identify a method to locally apply heat and to debond the assemblies. Disacop demonstrated the relative advantages of TPCs over their established alternatives. The recyclability and reusability of manufactured parts by disassembly is now a reality. Aerospace manufacturers and suppliers as well as society stand to benefit from the economic and environmental gains.

Publications

Lemke, C.; Wolfahrt, M.; Reppe, M.; Ladstätter, E.; Drechsler, K.: Disassembly of fusion-bonded thermoplastic composite structures. Second European Symposium on Aircraft Recycling, 2015

Henne, F.; Ehard, S.; Kollmannsberger, A.; Höck, B.; Sause, M.; Drechsler, K.: Thermoplastic in situ fiber placment for future solid rocket motor casing manufacturing. SAMPE Europe SETEC 14 - Efficient composite solutions to foster economic growth, 2014

Acknowledgement

This project has received funding within the framework of the FP7-JTI - Specific Programme "Cooperation": Joint Technology Initiatives of the European Union under grant agreement No 323420 (“Disassembly of eco-designed helicopter demonstrators”). This publication reflects only the author’s views and the European Union is not liable for any use that may be made of the information contained therein.

Contact Persons

Dipl.-Ing. Kalle Kind; Dr.-Ing. Swen Zaremba