MaTaInH2 – Material-Efficient and Cycle-Time Optimized Industrialization of H2 Pressure Tanks

The aim of the project is to industrialize the large-scale production of hydrogen pressure vessels while reducing costs.

Project Partners

MAHLE Filtersysteme GmbH Stuttgart, Leibniz-Institut für Verbundwerkstoffe GmbH

Duration

01.10.2020 – 30.09.2023

Funding authority

Federal Ministry of Transport and Digital Infrastructure (BMVI)

Motivation

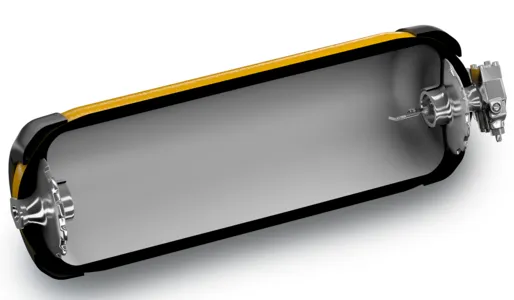

In the transition of our energy system towards renewables, hydrogen offers promising potential as a new energy carrier, due to its three times higher energy density compared to petroleum. Type IV pressure vessels are a key element for hydrogen and fuel cell technology in order to provide sufficient amounts of hydrogen in electrically powered vehicles for long ranges. The project MaTaInH2 is focusing on the development of a material-efficient and cycle-time-optimized production of pressure tanks to enable the realization of a marketable solution for hydrogen storage for mobile applications at 700 bar.

Method

The development of stable and robust processes is intended to achieve low scrap rates and high material quality, as well as increased material efficiency in the winding process. Furthermore, since pressure vessels are safety-relevant components, it is essential to develop suitable quality assurance methods. High process speeds create the basic foundation for the industrialization of large scale production. On this basis, a production line concept and manufacturing layout can be developed for a large-scale process according to automotive standards. The TUM is working on material and process development. In addition to cost and performance of the process, the focus is primarily on aspects of material quality.

Acknowledgement

The chair thankfully acknowledges the funding of the project “MaTaInH2 – Material-Efficient and Cycle-Time Optimized Industrialization of H2 Pressure Tanks” within the framework of the National Innovation Program Hydrogen and Fuel Cell Technology with a total of 1,520,121 euros provided by the German Federal Ministry of Transport and Digital Infrastructure (BMVI). The funding directive is coordinated by NOW GmbH and executed by Projektträger Jülich (PtJ). (funding code: 03B10111B)

Contact Persons

Elisabeth Gleis, M.Sc.; Youssef Mraidi, M.Sc.; Dipl.-Ing. Kalle Kind; Dr.-Ing. Swen Zaremba