TRANSITION – Tool-Part-Interaction simulation process linked to laminate quality

The focus of this project is the development and deployment of a process simulation tool for the reduction of development costs, time and the rejection rates of complex and highly integrated carbon fiber reinforced parts which are manufactured using autoclave technology.

Project Partners

Saab AB, Linköping, Sweden

Duration

30.08.2016 – 31.12.2019

Funding authority

European Commission

Motivation

The use of traditional trial-and-error approach for producing complex and highly integrated carbon fiber reinforced plastics (CFRP) parts leads to high development times and costs. Additionally the inherent variability in manufacturing leads to variations in the final part quality such as uneven part compaction and porosity, which bears the risk of increase in rejection rates. The goal of this project is to eliminate the above mentioned challenges by developing and introducing a process simulation tool early in the design phase. This tool will be used for the prediction of compaction behavior of CFRP parts made out of autoclave prepregs and also the resulting porosity content in these parts.

Method

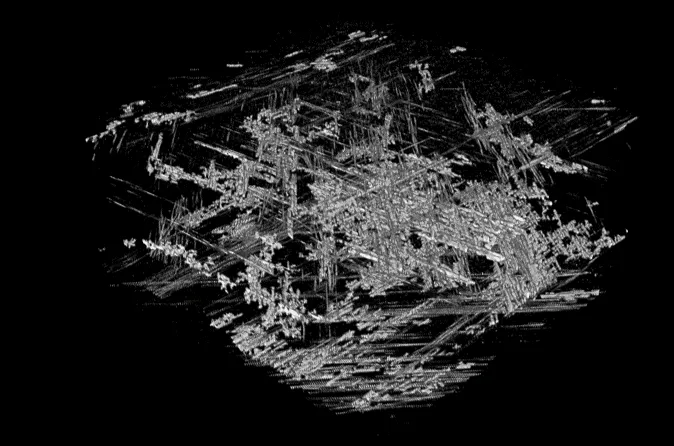

In this study a material model has been developed for the description of consolidation process of prepregs during the autoclave processing. In order to generate inputs for this model, the prepregs have been characterized extensively for their compaction, friction and bending stiffness. A bubble growth model has been integrated into the simulation work flow to track void growth and collapse and predict the final porosity distribution. These models will be validated using L-shaped laminates which is a simplified example of a complex CFRP part. For this purpose the compaction pressure during autoclave manufacturing of L-shaped laminates, their final thickness distribution and their porosity content will be used.

Publications

Copony, M.; Hartmann, M.P.: Towards a simulation strategy to predict laminate quality and porosity for partially impregnated CFRP prepregs. CAMX (The Composites and Advanced Materials Expo.) Conference Proceedings. Orlando, Florida, USA, September 11-14, 2017.

Acknowledgement

This project has received funding from the Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 717145. This publication reflects only the author’s views and the European Union is not liable for any use that may be made of the information contained therein.

Contact Persons

Dr.-Ing. Swen Zaremba