Luciano Avila Gray, M.Sc.

Research Group Leader

Tel.: +49 (89) 289 - 15203

Mobile +49 (152) 22947210

E-Mail: luciano.avila-gray(at)tum.de

Matrix characterization

The main function of the matrix is to distribute the load among the fibers, keep them in place and protect them from external and environmental agents. Thus it is very important that during the processing of the material the fibers are “wetted” by the matrix with a minimum content of voids. The matrix is then required to have certain properties during processing as well as service.

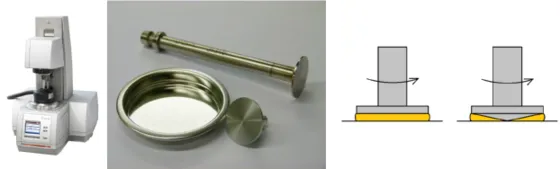

Rheological behavior

To ensure the wetting of the fibers by the matrix, it is very important to know its rheological behavior. This means knowing the evolution of the viscosity during the processing. In the case of thermo set resins, the time until the curing starts to take place (Gel Time) is of great importance since it determines the processing time window. For thermoplastics it is critical to know at what temperature the viscosity is low enough to allow the processing.

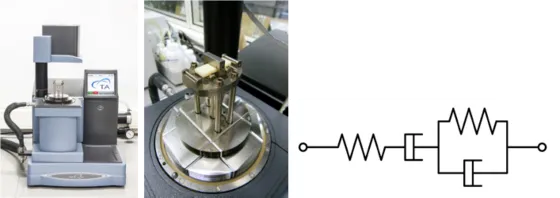

Viscoelastic behavior

Polymers are viscoelastic. Their mechanical behavior is a combination of elastic (tension proportional to strain) and viscous (tension proportional to strain rate) responses. This explains phenomena such as creep, stress relaxation, shape recovery and strain rate dependent stresses. Composites inherit these characteristics. Therefore is of great significance to determine the viscoelastic parameters that describe the material to understand its behavior under different loading conditions (static force, impact, cyclic loading). Both rheometry and dynamic mechanical analysis (DMA) are appropriate techniques to study this behavior.

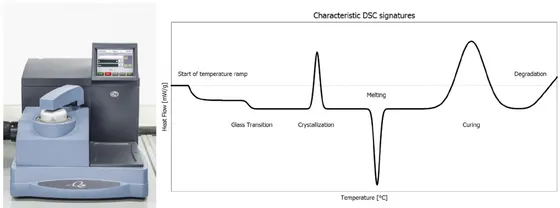

Glass transition temperature (Tg)

The glass transition temperature, denominated Tg, is an important material parameter present in both thermo set and thermo plastic polymers. The Tg determines the application window of the respective polymer. Above this characteristic temperature, the polymeric chains or chain groups gain mobility, which for example results in a reduction of stiffness and strength. This glass transition temperature may be determined using differential scanning calorimetry (DSC), dynamic mechanical analysis (DMA) and rheometry.

Curing enthalpy

The cross linking reaction taking place during the curing of thermoset resins is exothermic. Each matrix system has a characteristic curing enthalpy. Measuring it, using differential scanning calorimetry (DSC) can be useful to estimate the degree of curing, to evaluate the thermal evolution of a part during processing or to determine the effect of aging on uncured resins.

Crystallinity

In the case of semi crystalline thermoplastics, the crystallinity is in close relation with the thermal history in particular during processing. The mechanical properties of the material are strongly affected by the crystallinity fraction, which can be determined also with the help of DSC measurements. Knowing the melting and solidification temperatures are of great use during the optimization of production processes for thermoplastic polymers and composites.

Microstructural characterization

The properties of a composite, such as its elasticity, strength and fracture toughness, will depend on the type, amount and distribution of the individual constituents within the material.

Component fraction analysis

The mechanical properties improve as the amount of reinforcement increases. Production cycles are also affected by the fiber-matrix ratio. The mechanical properties may further be affected by excessive presence of porosity, since the matrix is then not able to effectively transmit the force among the fibers. The LCC has the necessary facilities to determine the percentage of each component, including voids, by dissolution of the matrix using sulfuric acid (DIN EN 2564).

Fiber architecture

In addition to a specific fiber-matrix ratio, the material properties of the composite are determined by the distribution and architecture of the reinforcing fibers. The microstructure of the composite can be studied by means of material microscopy.

Equipment

The above mentioned matrix and microstructural characteristics can be analyzed at the chemical laboratory of the LCC using the following instruments:

Thermal analysis:

• Differential Scanning Calorimeter, TA Instruments Q200

• Dynamic Mechanic Analyzer, TA Instruments Q800

• Rheometer, Anton Paar MCR 302

Micrography:

• Automated grinding and polishing machine, Struers Tegra

• Stereo microscope, Olympus SZX10 with adjustable LED illumination ring

• Materials microscope, Olympus BX41M with 5x, 10x, 20x, 50x, and 100x magnification

• Digital cameras Olympus SC30 mounted on both microscopes

• Image acquisition and analysis software: Olympus Stream Motion