INSCAPE – In situ manufactured carbon-thermoplast curved stiffened panel

INSCAPE’s main objective was to enhance the automated thermoplastic fiber placement process and machine to manufacture an in situ consolidated (AFPisc) double-curved structure including in situ joining of stiffeners and skin laminate.

Project Partners

AFPT GmbH, FACC AG, INEGI – Institute of Science and Innovation in Mechanical and Industrial Engineering

Duration

01.01.2016 – 31.05.2018

Funding authority

Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme

Motivation

The production strategy AFPisc is a fundamental change compared to the state of technology, where composite structures are typically built within process chains. AFPisc integrates the major steps of material deposition and consolidation and represents a technology today considered as additive manufacturing. The project INSCAPE developed a new manufacturing approach for future lightweight structures for application in aerospace which enables a more environmentally friendly production, improved recyclability after end of use and a higher productivity due to an automated manufacturing setup with high reproducibility and flexibility. It shall therefore strengthen the future production of aerospace structures in highly developed societies with the ambition of high ecological and social standards.

Method

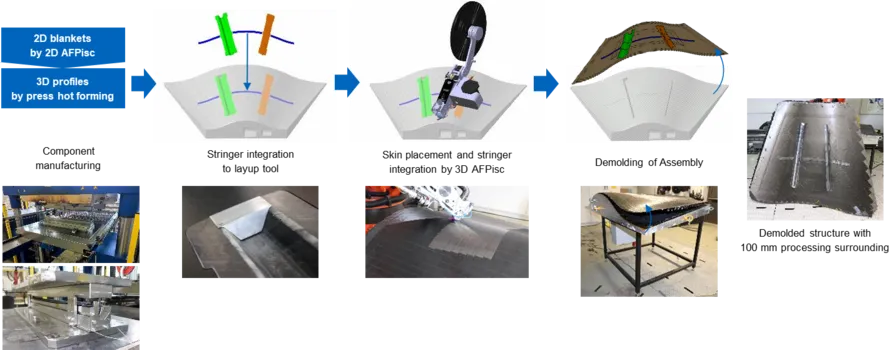

The aim of the applied project was to develop an advanced additive manufacturing process beyond the state of the art which enables light-weight design at proper mechanical performance under ecological friendly conditions. INSCAPE’s new in situ manufacturing and joining process was shown by the demonstrator part which was realized using a combination of laser-assisted TP-AFP and thermoforming process (for stiffener elements only). The main challenges were:

- In situ placement of customized blanks with the TP-AFP head; the thermoplastic tapes were laid and consolidated in one step (in situ) before hot forming instead of applying a cost and energy intensive additional consolidation process.

- In situ joining of the stiffened structure; the stiffeners were placed into recesses in the curved mold; the skin layers are directly (in situ) placed onto the stiffener flanges; no further joining between the parts was needed.

- Improve process performance in terms of material throughput, process robustness and laminate quality also in terms of multi tow operation.

Publications

Wettemann,T.; Henne, F.; Schneiderbauer, G.; Pinto, R.; Drechsler, K.; Ladstätter, E.; Tejerina Hernanz, R.: AFP in-situ consolidation processing. SAMPE Journal (54), 2018, 26-36

Wettemann, T.; Henne, F.; Schneiderbauer, G.; Pinto, R.; Drechsler, K.; Ladstätter, E.; Tejerina Hernanz, R.: A contribution on TP AFP in situ consolidation processing and the opportunity to produce high performance composites in an additive manner. SAMPE Europe Conference 2018, 2018

Acknowledgement

This project has received funding from the Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 686894. (“In situ manufactured carbon-thermoplast curved stiffened panel”). This publication reflects only the author’s views and the European Union is not liable for any use that may be made of the information contained therein.

Contact Persons

Dipl.-Ing. Thomas Wettemann; Dr.-Ing. Swen Zaremba