MAI Plast – Development of Cost-Efficient Production Technologies for Automated Processing of Thermoplastic High Performance Composite Materials for Large-Scale Production Scenarios

Making thermoplastic high performance composite materials cost-efficient

Project Partners

Audi AG, BASF SE, BMW AG, Siemens AG, SGL Carbon GmbH, Airbus Group Innovations, Thermoplast Composite GmbH, Airbus Helicopters Deutschland GmbH, Premium Aerotec GmbH, KUKA Systems GmbH, Voith Composites GmbH & Co. KG, Universität Augsburg, Fraunhofer-Einrichtung für Gießerei-, Composite- und Verarbeitungstechnik IGCV, Fraunhofer-Institut für Werkzeugmaschinen und Umformtechnik IWU, Deutsches Zentrum für Luft- und Raumfahrt e. V., TEC-KNIT CreativCenter für technische Textilien GmbH, Krauss-Maffei Technologies GmbH

Duration

01.07.2012 – 30.06.2015

Funding authority

German Federal Ministry of Education and Research

Motivation

Due to fundamentally new concepts in mobility, lightweight construction technologies, like the use of carbon fiber reinforced plastics, have gained in importance in all transport applications. Current fiber reinforced plastics usually use thermoset matrix systems. The available resin systems have some drawbacks compared to thermoplastic resins, e.g. regarding cycle time, energy consumption, shelf life and recyclability. Moreover, current production processes often involve a high degree of manual work and are time consuming. The alternative use of thermoplastic matrix material enables reduced processing times, including both the automated production as well as efficient joining technologies.

Method

The Chair of Carbon Composites worked on three major topics within this project:

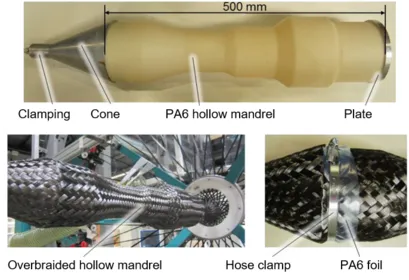

(1) Braiding with thermoplastic mandrels: Both the manufacturing of a thermoplastic, hollow mandrel as well as the overbraiding technology with carbon fiber are state of the art. The scientific and technical goals were therefore as follows:

- The wall thickness of the thermoplastic mandrel had to be optimised regarding stability of the mandrel, fiber volume fraction and impregnation behavior. Both the necessity to introduce additional foils in components with multiple layers and the behavior of different matrix materials were studied.

- The flow and impregnation behavior of the matrix was examined in order to achieve an optimum part quality by adjusting processing pressure and temperature in combination with constructive measures.

- The consolidation and forming process had to be carried out under tight dimensional tolerances. A subsequent trimming of the part was not allowed. Thus, various concepts for a defined and controlled forming were investigated (e.g. deliberate points of kinking or precise local warming). Also, different warming concepts like infrared, heated tools or a combination of measures was investigated.

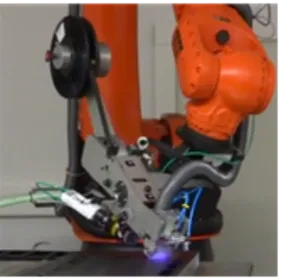

(2) Further development of thermoplastic AFP and efficient use of material through local reinforcement structures: The scientific goals regarding thermoplastic AFP were an improvement of the relations of the processing parameters consilidatoin temperature, pressure, speed of the consolidation roller and the influence of these parameters on part performance, specifically on mechanical properties and porosity. It was sought to get in better control of the thermal stresses in the part by investigating their dependency form the said process parameters. The increased process knowledge, also regarding the processability of various materials, lead to the minimization of up to then inevitable cut and waste material. Moreover, the efficient combination of different placement technologies was investigated with other project partners from aviation and automotive.

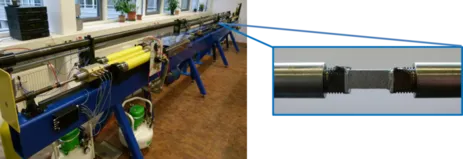

(3) Strain rate dependency: The chair determined material properties required for automotive crash simulation. To gain knowledge about failure initiation and propagation of fiber composite materials under crash loading, particularly the following effects were investigated:

- Influence of the loading velocity on the different intralaminar failure modes and the energy release rates for matrix tension, matrix compression, fiber tension and fiber compression.

- Influence of the loading velocity on the interlaminar failure modes, particularly mode I (failure due to normal stresses in thickness direction) and mode II (failure due to shear stresses between single layers of the laminate).

It is to be noted, that testing methods for the experimental investigation of the delamination and failure behavior under crash were developed further or even completely new conceptualised following quasi-static standards because there were no standardized test methods for this high strain rate regime.

Publications

Plöckl, M.; Kuhn, P.; Körber, H.: Characterization of unidirectional carbon fiber reinforced polyamide-6 thermoplastic composite under longitudinal compression loading at high strain rate. 11th International DYMAT Conference, 2015

Acknowledgement

The chair thankfully acknowledges the funding of the project “Entwicklung kosteneffizienter Verarbeitungstechnologien zur automatisierten Prozessierung von thermoplastischen Hochleistungsverbundwerkstoffen für Großserienanwendungen – MAI Plast” provided by the German Federal Ministry of Education and Research under the leading edge cluster MAI Carbon (funding code: 03MAI01M).

Contact Persons

Dipl.-Ing. Kalle Kind; Luciano Avila Gray, M.Sc.; Dr.-Ing. Swen Zaremba

Final Report

External link (pdf)